Lean is used in many institutions to improve processes in professional services from improving exam logistics to the running of counselling services. At Northumbria University, they are also applying lean techniques to research management processes, as David Young explains.

I’ve previously written on Efficiency Exchange about our work to apply lean principles to processes within research management and administration at Northumbria University.

Research management is now a common support service in higher education (HE) and in many cases has evolved to meet the needs of a complex range of stakeholders. It is therefore likely that not all of the processes involved in managing research are optimal or efficient.

Our three-person team, based in research and business services at Northumbria, has been focusing on applying lean thinking to two processes:

- Grant transfers into an institution: this happens when an academic moves to a new institution to take up a different job during a funded project. There are multiple internal and external stakeholders involved with varying roles, demands and goals (including the academic themselves, the HEI they are leaving, and the funder).

- Setting up consultancy with external companies: an external client may want to access specific knowledge or expertise within a university to solve a specific problem. Businesses typically expect prompt replies and quick turnarounds, but the university will need to ensure an appropriately costed contract is in place before work starts.

This post summarises the lessons we’ve learned so far.

Getting to grips with lean

When we started this journey we spent time understanding lean’s core concepts, tools and techniques and how it has been applied in HE. This was important because our project is relatively small and none of us consider ourselves to be experts in lean, nor is this part of our “day job”.

We were attracted by the core principle that lean is about respect for people and involves staff who actually deliver a service in decision-making and continuous improvement. The UK lean HE community has been tremendously helpful throughout the process: we have had valuable input from lean experts in other institutions as well as academics working on lean at Northumbria.

Four key points for success

Our work has highlighted four points which have been key to our progress so far:

- Identifying value/stakeholders: In both processes there are at least two key stakeholders: the academic (transferring the grant or carrying out consultancy) and the funder. What both want is for the work to get started as soon as possible. Nevertheless, as a service department we must be aware of the university’s needs, for example financial and legal requirements which may be unavoidable and add time to the process – “non-value adding processes”, in lean terminology.

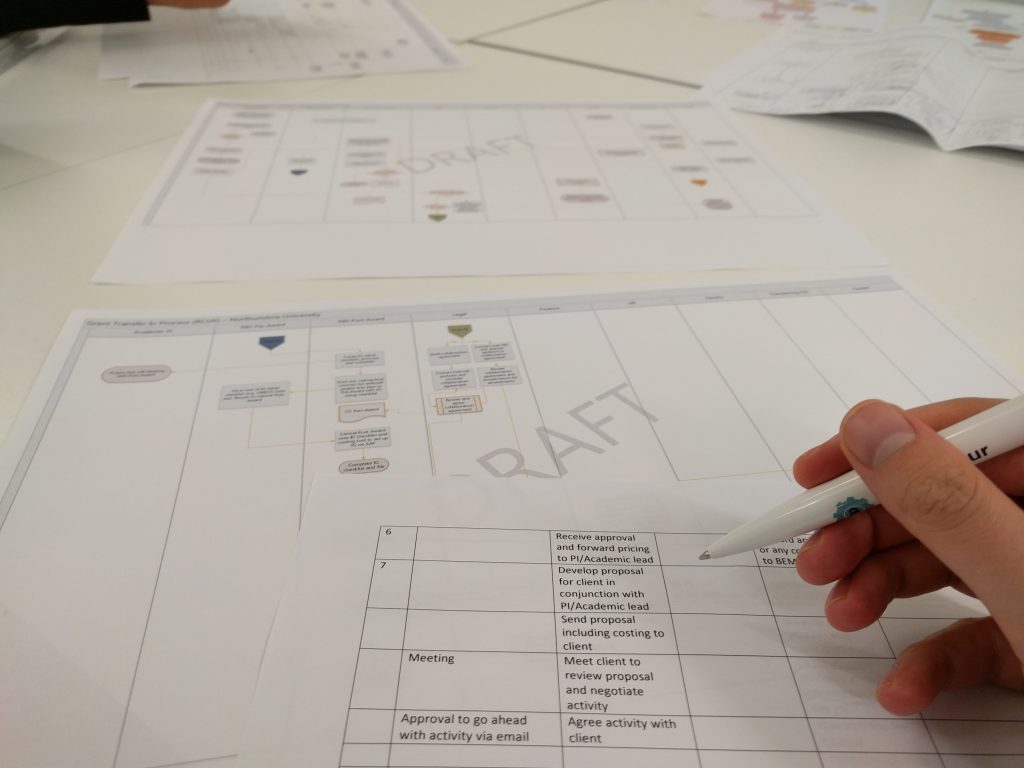

- Involving stakeholders to analyse existing processes: Both the pre- and post-award teams in Research and Business Services are critical parts of both processes so we needed their input to get a full picture. In a workshop with representatives from these teams, we mapped out the processes using a “swim lane“ approach to clearly show areas of responsibility. In the grant transfer process nine separate stakeholders were identified including: academic principal investigator, research and business services, legal, finance, HR, faculty executive, the transferring HEI and funder. The process mapping exercise is beneficial as it starts to highlight areas where there may be uncertainty, confusion or duplication, i.e. “wastes” from a lean perspective.

- Agreeing metrics to measure success: “Value stream mapping” was suggested by an academic expert as a way to quantify wasteful steps. It involved another workshop to take the existing process flows and estimate the range of time taken on each step. In this way we can calculate the total amount of time for each full process as well as the time taken by each stakeholder. It also enables us to redesign areas of the process and suggest improvements, which can then be measured to assess how much time they have saved.

- Understand and accept what you can’t change: In any process involving multiple internal and external stakeholders there are likely to be steps which are non-value adding and over which you have little or no control. In our project we quickly identified steps owned by other service departments which, from our perspective, appeared to add little value to the process. However, given the limited scope of this initial project we needed to accept what we could and could not alter and we found that there were still several areas which could be changed. Even though these were small relative to the whole process, cumulatively they can deliver a significantly leaner process.